PATTERNMAKING

Mold patterns are expected to be designed before they are made. Due to our in-house capabilities, we are in a position to make patterns using both customers' drawings and our own. After a particular drawing is issued, design of a manufacturing process for the relevant pattern begins. Based on the data obtained, the process is designed using the 3D modeling in SolidWorks. This involves the following stages:

· designing computer simulation models in SolidWorks for a part;

· designing a manufacturing process for the relevant pattern (splitting the pattern into separate structural elements);

· designing computer simulation models for the structural elements;

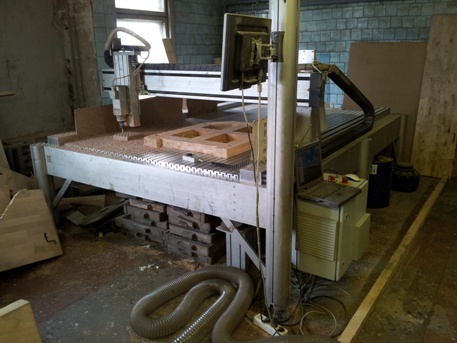

· designing an NC code for a CNC machine;

· manufacturing the structural elements;

· ongoing quality control inspection of completed patterns.